The commentary of the light(Lamp) heating

2

2121

1.The summary of the light(Lamp) heating

The light heating method of our company condenses the light of the halogen lamp with a concave lens and gets a high temperature.(MAX.1400℃,2600F)

The collecting pattern of the heater has a point (a circle) light condensing type and a line (belt-shaped) light condensing type.

We call the heater of the point light condensing type a ”spot heater”in our company and call the heater of the line light condensing type with a ”line heater”.

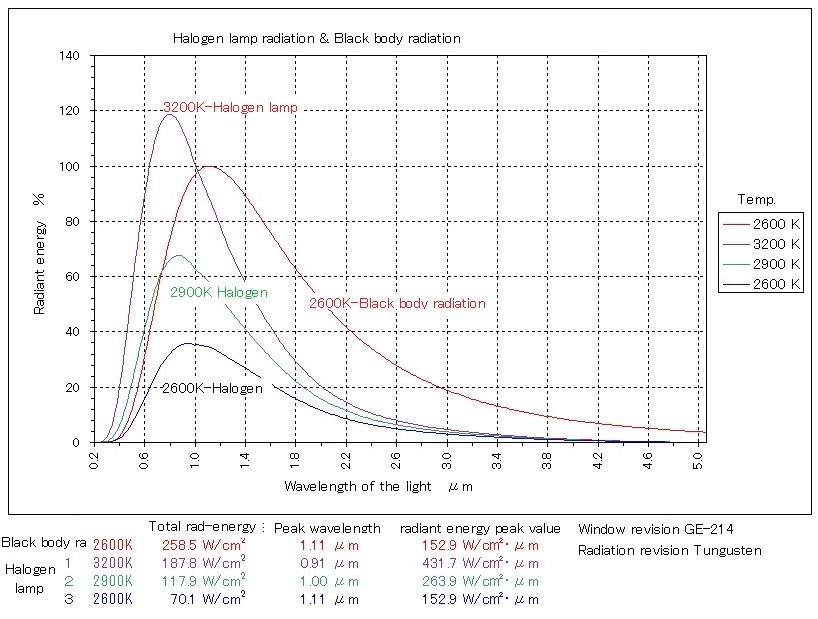

ハWavelength area of the light of the halogen bulb is 0.4-2.5μm area to assume approximately 1μm a peak.

This is the thing which is near to solar direct ray light.

When I compare a halogen bulb method with other light heating methods, there is the following characteristic

| 1 | The item to compare | halogen lamp | far infrared rays heater | Laser | xenon lamp |

| Conversion efficiency to light |

◎about90% | ○about70% | △ | △〜○ | |

| High-density irradiation (ability for high temperature heating) |

◎about1400℃ (2600F) |

△about400℃ (750F) |

◎unlimited | ◎about1800℃ (3300F) |

|

| Shortness of the boot-time |

◎ | × | ◎The pulse is possible, too | ◎The pulse is possible, too | |

| Low cost |

◎ | ◎ | △ | △ | |

| Littleness of the size |

○ | ○ | △ | △ | |

| Ability to heat from a long distance |

○ | △ | ◎ | ◎ | |

| Ability to heat metal |

○ | × | ◎choose the wavelength | ○ | |

| Ability for heating of the nonmetallic material |

◎〜△ | ◎ | ◎choose the wavelength | ◎〜△ | |

| Ability for heating through the glass |

◎ | × | ◎choose the wavelength | ◎ | |

| Ability to heat in clean |

◎ | ◎ | ◎ | ◎ | |

| Ability it infiltrates a semitransparent object, and to heat |

○ | × | ◎choose the wavelength | ○ | |

| Safety |

○ | ○ | △ | △ |

When generalize the above; the characteristic of the heating method with the halogen lamp

(1)Conversion efficiency to light (radiation) is very high

(2)Rise time of heater is extremely short(about 1sec.)

(3)Cost is low (with an initial, the running)

(4)Can heat to a high temperature.(MAX.1400℃/2600F)

(5)Heating through the glass is possible

The above is a notable item. There is the characteristic that it seems to be follows as

well as it.

(6)It is wavelength area to be suitable for metal heating.The only difference that is bad that

absorption is good for the nonmetal is big

Reference data The emissivity (=absorption factor) of the material

(7)Light seeps to a semitransparent object(skin and paint or adhesive) inside and heats from

the inside.

(8)Because a halogen lamp is a product made in quartz glass, there is not outbreak of a dust

and gas and is suitable for the use in the clean room

But it is necessary to make a lead wire or the end processing clean room specifications.

(9)The halogen lamp is relatively safe for the human body, others.

The laser is at increased risk of going blind.

The xenon lamp is at increased risk of (it is high pressure enclosure lamps more than 5 times

of the halogen lamp), the explosion.

In addition, ultraviolet rays appear abundantly and use the high voltage (30kv).

2.A choice method of the light heating arrangement

A point light condensing type (The Spot Heater)

When you want to heat in a case and the circle that want to heat an object at a point, please choose "a point light condensing type"The Spot heater".

It is relatively easy to design the point light condensing type for light distribution of the hope by controlling a mirror curve.

But please talk because it may be impossible by the demand contents.

As for the spot heater, as for the irradiation distance, short one is favored.

Because there becomes little loss of the light energy, and a high temperature is provided more.

Because we can make it with an NC lathe, even a special order product is relatively cheap and can make (a spot heater).

A line light condensing type (The line heater)

When you want to heat linearly, please choose The line heater.

It is only a width direction of the light condensing that we can control the line light condensing type by a mirror curve and cannot control the length direction with the mirror.

When it is necessary to heat the length that is a length direction, it is necessary to lengthen the line heater enough than the necessary heating length.

We can widen uniform heating width, but it is carried out an activity having difficult both design and production by controlling the emission of light pattern of the lamp.

In this case the ranges that can heat uniformly increase so that irradiation distance is short.

By angle θ which leaves the center when distance becomes very long almost (become the irradiation strength to damp in COSθ )^ 2.)

Temperature generally lowers only with a line heater heating the whole an edge.

You install a line heater heating only an end particularly to supplement this, and, in coordination with its output, there is the method to regulate so that it is to the temperature that the whole is uniform.

The standard line light condensing type mirror uses an extruded shape of the aluminum.

We become the processing in the milling machine, and therefore the special order mirror except the standard becomes expensive.

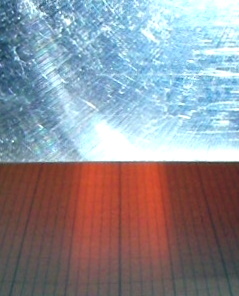

The comparison between aluminum mirror and gold-plated mirror

The main body of heater makes both the point light condensing type and the line light condensing model with aluminum.

It is an aluminum mirror we polish the aluminum, and to have made the mirror surface.

Because reflectance for the emission light of the halogen lamp is a little less than 90%, the aluminum mirror is inferior to a gold-plated mirror doing a postscript at reflectance like chart below.

In addition, reflectance falls by the oxidation a little when the aluminum mirror uses it for a long term.

However, there is the merit that re-abrasion is easily possible in the case of an aluminum mirror in a user side.

The gold-plated mirror is the superior mirror in the purpose to reflect the radiant energy of the halogen lamp efficiently.

But I may damage the gilding depending on the kind of the dirt when I am stained with materials evaporating from a heating object.

But I may damage the gilding depending on the kind of the dirt when the plane of the mirror is stained with materials evaporating from a heating object.

In this case the gilding becomes the re-plating because you cannot restore it, and it costs expense of around 10,000 yen→100$ (the current price) per 100cm^2(15.5 square inch)

Therefore please warn it not to pollute it in the case of a gold-plated mirror.

The gold-plated mirror endures long-term use as far as you do not pollute it.There are very few falls of the reflectance, too.

For the device that does not pollute the mirror, it is to establish the glass window between a mirror and a heating object.

This glass window has to be able to easily clean if stained.

A quartz glass is suitable for the materials of the windowpane.

But a replacement includes crystallization glass because the quartz is a high price.

It carries away clean air in a mirror for a method except the above, and the method to make the mirror inside positive pressure is effective.

But this method is not effective when I do not make a mirror some sealing up structure with a glass window.

Therefore, this becomes the supporting means of the windowpane method.

3.About the appropriate usage of this heater

Summary

Because the light heating arrangement using the halogen lamp is halogen lamp itself basically, both the usage and the instructions are the same as the thing for the wearing appliance of halogen bulb and it.

There is easily 0-100% of-like light only by control of the voltage in the same way as a general halogen lamp lighting equipment.

But a cooling problem often occurs for the size of the appliance because the output (electricity) is big.

We adopt water cooling or a forced air-cooling with the high-power light heating arrangement.

Measures for the rush current to a lamp

A plunge electric current to reach than normal 5 times when the halogen bulb adds the rating voltage suddenly drifts for a short time, and this gives a halogen bulb and the power-supply unit bad influence.

This influence becomes remarkable as the big lamp of the current value.

In the case of lamps more than 10A by all means! Even in the case of the lamp of the current value that is lower than it, please use a soft(slow) starts power supply more than it belonging to as much as possible for one second.

⇒Actual survey data of the rush current

A breaker works by this rush current depending on power-supply unit and cannot turn on electricity.

Please refer to the power supply maker precisely.

The halogen lamp (more than 300w) of the large electricity uses most AC power supplies, and, in that case, as for the control of the electricity, what I perform by phase control (thyristor control) is common.

Therefore there is much power-supply unit attached by default simpleness the thyristor controller incorporating a soft(slow) start function.

Instructions not to narrow the life of the heater

Please do not add the voltage more than the rating voltage as much as possible. It causes disconnection and melanism, the explosion.

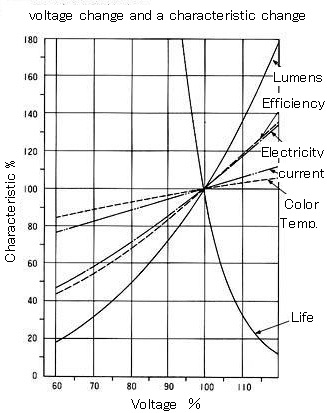

It is advantageous to lamp life to have you use it with the voltage as low as possible as far as you satisfy a necessary heating condition

For example, the life is increased approximately three times by 10% of voltage drops.

you are used in interchange, but it is dangerous to be going to get the appropriate voltage by phased control (thyristor control) from the voltage that is higher than the rating voltage.

In this case the high voltage increases momentarily even if actual value of the voltage is less than the rating voltage.

IA lamp causes a breakdown for this inside and may do disconnection and an explosion.

With the AC power supply which is equal to the rating voltage of the lamp for a power supply, it is right how to use that control it in the direction lowering the voltage by phased control (thyristor control).

Please do not add vibration and a shock to the main body of heater and a halogen lamp as much as possible.

When a shock is strong, glass is broken, and a filament is snapped.

However, even if these abnormality is not seen definitely, damage may be left to the filament and leads to a fall of the life.

There is not the limit of the lighting direction on the lamp of the point light condensing type.

However, you use the heater of the line light condensing type by horizontal placement.

This depends on the structural characteristics of the halogen lamp to use for this heater.

However, please talk because it is possibility I design the halogen bulb corresponding to the perpendicular lighting, and to produce.

About the cooling of the heater

With the model that a coolant is necessary, please drain coolants more than 0.5 L/min. per lamp electricity 1kw.

For example, in the case of a heater of 2kw, You are more than 1 L/min.

The water temperature rise of this time becomes approximately 10 degrees Celsius.(about20F)

Please drain around 2 times of at least necessary flow quantity if possible.

It is desirable for the power supply of the lamp to attach cutting interlock when water stops.

The water-cooled type assumes what is used by the water pressure that is lower than 200kPa( about 2kgf/cm^2) degree and designs it and produces it.

Please talk when it is used by the water pressure that is beyond 300kPa.( about 3kgf/cm^2)

The thermal energy that much light heating arrangement occurs in a mirror part is about 1/3 of the electricity.

So you must cool about 1/3 of the electricity that you supplied to a heater.

In this case if it is a heater of the small electricity, even natural cooling is possible, but water cooling or a compulsion air-cooling is necessary when it is with a compact device with large electricity.

When water temperature is considerably lower than outside temperature, in cases used the subsurface water for as a coolant, dew condensation becomes the problem.

When there is much dew condensation, a heater short-circuits for you, and you may get shocked, and evil may influence the reflectance of the mirror again.

In this case please supply it to a heater after having reduced differences between water temperature and outside temperature.

Or when I do not turn on electricity, the coolant stops, and please take measures to make quantity to flow during electricity minimum.

An alien substance accumulates in the cooling waterway depending on the quality of the water of the coolant and gets into trouble.

In addition, corrosion of aluminum constituting a heater depending on the quality of the water is generated, and the aluminum compound may accumulate.

In addition, corrosion of aluminum constituting a heater depending on the quality of the water is generated, and the aluminum compound may accumulate.

Others

Please warn it not to pollute the lamp at the time of lamp exchange.

When you pollute a lamp, please wipe it off with the cloth which you soaked with alcohol neatly.

The reflecting mirror side of this heating arrangement is the most important, and is a place needing maintenance most.

When smoke generated by evaporation or the combustion of the heating object attaches to a mirror side, performance largely falls.

When you heat such a heating object, you install protection glass in the front of the light heating arrangement and sometimes clean this, and please change it.

It carries away clean air to the heater inside and can completely prevent an approach of the smoke to a heater if you make the inside positive pressure.

We are highly precise and make the lamp exchange the design that you can get by simple operation.

But please do not dismantle the heating arrangement body section.

4.Instructions to use it safely →Please protect danger to the human body

The main body of heater and the lamp become the high temperature.

So please warn it not to cause a burn and the fire enough.

In addition, similar attention is necessary because the space close to the collecting department becomes the high temperature.

The danger that the glass electric bulb of the high pressure enclosure such as the halogen bulb explodes is not zero.

Because the quartz glass piece of the high temperature (more than 600 degrees Celsius) is scattered when a lamp explodes, you are very in danger.

Please use it under the appliance and the condition that were designed even if it explodes so that there is not danger to a fire or the human body to avoid this danger.

In addition, please insert appropriate speedy decision FUSE in the power supply line.

As for the explosion, in the case of most, arc discharges happen in the lamp inside after a filament was snapped and inside pressure rises at the high temperature by it and explodes.

Therefore, the beginning that a lamp of the high voltage is as for the explosion of the lamp breathe it (because an arc discharge happens at the time of disconnection)

The explosion has little rating voltage with the lamp of the low voltage of 24v.

But please be careful because the possibility is not zero.

The irradiation to the human body in the high illumination needs attention in a thing (1/10 of the light of the sun) of that the ultraviolet rays which are harmful to the human body are included in in spite of being a very small amount in the characteristic for the light of the halogen lamp for a long time.

The ultraviolet rays which are harmful to the human body are included in the light of the halogen bulb in spite of being a very small amount (1/10 degree of the light of the sun)

Therefore, the irradiation to the human body in the high illumination needs attention in long time.

In addition, an ultraviolet rays cut filter may be necessary by the heating uses of the ultraviolet rays hardening resin.

In addition, the light that is strong even if it is not ultraviolet rays is harmful to eyes.

When I watch the collecting department of a lamp and the spot heater turning on, please protect eyes with dark sunglasses.

Please do not get the light(Lamp) heating arrangement (HSH, LHW) wet.

Please ground the Heater body for safety.

The lamp exchange please confirm that a power supply becomes OFF.

5.About the collecting diameter (width) of the light(Lamp) heating heater

The light condensing diameter in the place where squeezed an irradiation diameter with a collecting model light heating heater most seems to be follows; is related.

1.The collecting diameter of the heater is almost proportional to the opening diameter of the mirror reversely.

2.The collecting diameter is almost proportional to the focus distance (irradiation distance) and changes.

Narrow it down small so that the focus distance is short, and a high temperature is provided.

3.The collecting diameter is almost proportional to source of light size.

The filament diameter of the lamp is almost proportion to a square root of the electricity.

The irradiation diameter becomes big as (electricity is big) that a source of light is big.

Therefore the power density does not change if you use the big halogen lamp of the electricity only by an irradiation diameter becoming big.

The chart below shows a practical calculation method by these relations.However, it is an incorrect method academically.

It is a calculation when the above squeezes the collecting diameter of the heater, and it wants to make a small high temperature spot.

Please regard the focus diameter here as the range that almost becomes a center and the same temperature.

In addition, it does not make ends meet when the focus distance is extremely short either.

Generally, in the case of the mirror of the short focus, I become the focus spot diameter at the same level as source of light size.

When you want to heat a wide range, there is the method you can move it back and forth, and to use from the focus position of the heater.

We can make a heater corresponding to extensive heating with an exclusive design, but there are cost, the problem of the production period and should try it whether you can move it from the focus position if it is possible and can use it.

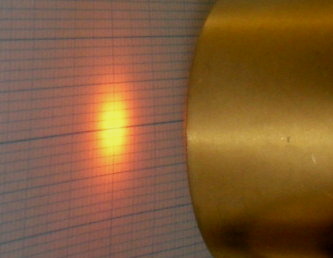

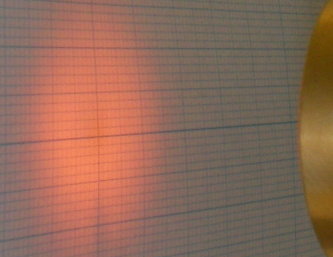

It is the photograph which showed an irradiation diameter when you changed irradiation distance, the change of the irradiation pattern as follows.

Model of "f=15mm" at distance of 10mm An irradiation diameter becomes big by approxi- mately equal distribution |

Model of "f=15mm" at distance of 15mm The state that bundle of rays were narrowed down to most because it was a focus position. The maximum temperature is provided |

Model of "f=15mm" at distance of 20mm An irradiation diameter becomes big, but central part is approximately strong |

Model of "f=15mm" at distance of 30mm irradiation diameter grows big, and is appro- ximately equal distribution |

As for the above, in the case of a point light condensing type (a spot heater), even a line light condensing type (a line heater) is similar Cf. photograph under →

The phenomenon that collecting width spreads through even if either direction can drag from the focus position is the same. However, the light distribution of the length direction gets longer one-sidedly so that distance leaves it.

Model of "f=20mm" at distance of 12mm Some centers are gloomy, but irradiation width becomes considerably wide |

Model of "f=20mm" at distance of 14mm Irradiation width becomes wide by appro- ximately equal distribution |

Model of "f=20mm" at distance of 20mm Because it is a focus position, irradiation condenses light thinnest |

Model of "f=20mm" at distance of 30mm Irradiation width becomes wide by appro- ximately equal distribution |

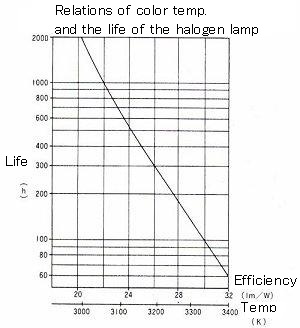

6.The characteristic of the halogen lamp

When the halogen bulb changes the voltage, various characteristics change.

If it is life to change most greatly and lowered the voltage 10%, as for the life, approximately three increase twice as much.

The lamp life is almost decided at the temperature (color temperature) of the filament.

Life is 200-300 hours in 3200K in color temperature 3000K for approximately 1,000 hours.

The life when temperature is largely lower than 3000K extremely gets longer in a calculation, but, as for the life as the lamp, it is not in various factors in a calculation street even if the calculation economic life of the filament becomes long.

5,000 hours are adopted for a rough price in 2600K, and 20,000 hours are adopted in 2200K.

The thing limiting the life of the lamp is not only filament temperature.

When seal part temperature is high, this limits the life of the lamp (cf. chart below).

| The characteristic change for the change of the voltage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|